WHAT WE DID…

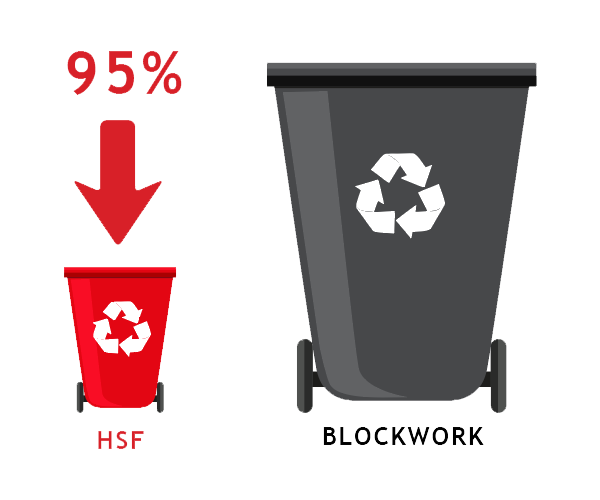

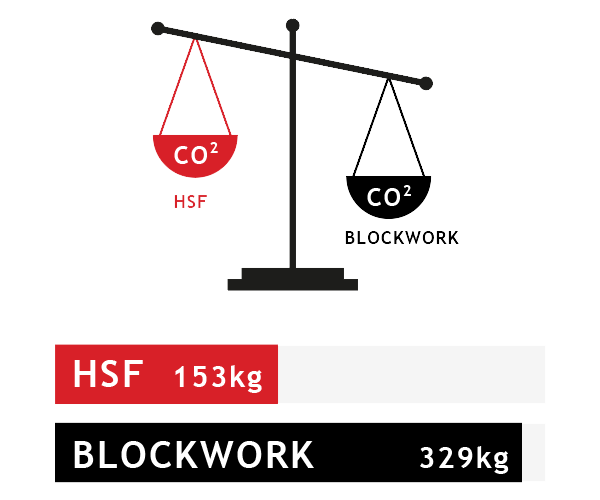

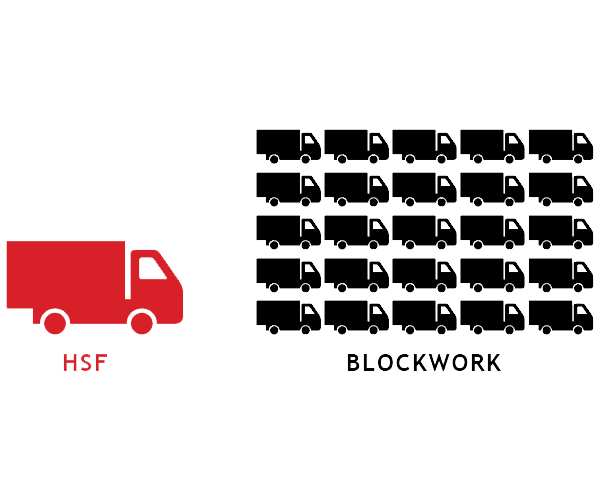

Faithful and Gould carried out an independent cost and programme comparison between Hadley Steel Frame System and Traditional Blockwork. The objective of the study was to determine the most cost-effective build method in the United Arab Emirates (UAE):